Have you ever wondered about the journey of your scope when it arrives at our repair facility? Here’s some insight on how the process works in 7 stages:

Have you ever wondered about the journey of your scope when it arrives at our repair facility? Here’s some insight on how the process works in 7 stages:

- Arrival

- Scope arrives via FedEx/UPS between 9 am-10 am. Free shipping of course!

- Initial Paperwork

- Our Operations Department creates inspection paperwork and places the scope in a plastic tub.

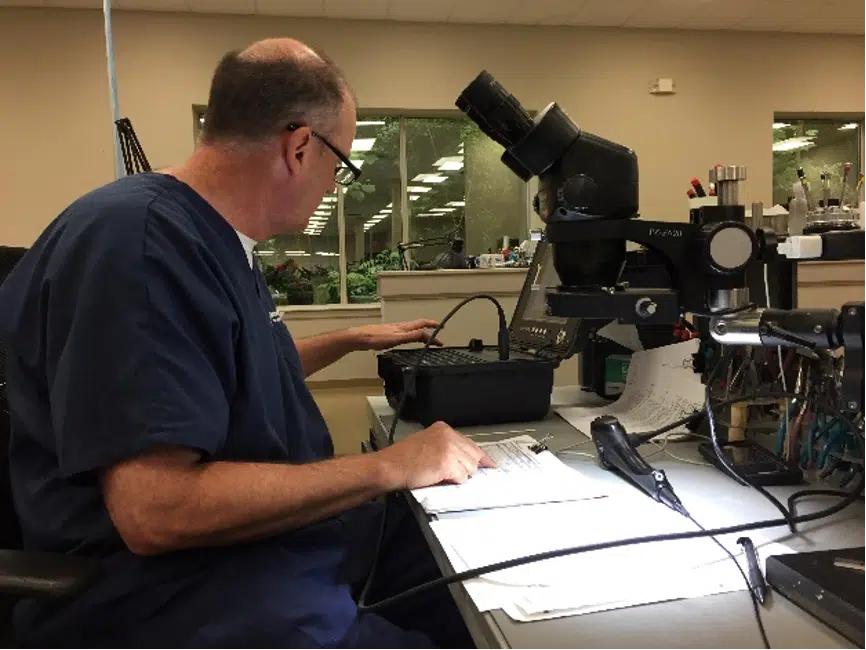

- Inspection

- The scope is handed to the inspector for inspection (33 point inspection process), where we test for image quality, complete a leak test, inspect all channels, etc. We do test the scope for additional issues other than the primary customer complaint.

- Most common repairs include: bending rubber replacements, angulation adjustments, and fluid invasion. Most of these are due to regular wear and tear on scopes.

- Customer Approval

- Once inspected, the scope goes back to operations to await approval from the customer. After approval, the scope is placed on the approval rack based on Major/Mid-Level/Minor repair.

Repair Process

- The technician begins the repair process.

- Most minor flexible endoscope repairs are finished within 24 hours. Major flexible repairs take about 3-5 days, as opposed to the OEM, which can take over a week.

- Most minor rigid endoscope repairs take 1-2 days. Major rigid repairs take about 4-5 days, as opposed to the OEM, which can also take more than a week.

- QC Process

- Once the scope is repaired, the technician performs a “Pre QC” on the scope before giving it to our “final” QC inspector.

- The scope is QC’d (24pt QC process) and then given to operations.

- Final Review

- Operations performs a “commercial QC”, which is mostly a cosmetic look over and quick cleaning before shipping scope back to the customer.

Check out our video of a day in the life of a scope:

Posted In: Blog

FREE SHIPPING Anywhere in the Country for Repairs

FREE SHIPPING Anywhere in the Country for Repairs Repair Process

Repair Process